Cracked pump collars are a common, frustrating problem, often leading to costly replacements and significant downtime. The traditional solution, cutting and welding, is messy, time-consuming, and can compromise the structural integrity of the collar. However, there's a better way. This article explores a revolutionary, no-cut method for repairing cracked pump collars, offering a viable alternative to traditional, destructive repair techniques. This approach prioritizes preserving the original collar, minimizing disruption, and extending its lifespan significantly.

We’ll guide you through a step-by-step process that utilizes advanced materials and techniques to achieve a strong, durable, and long-lasting repair. Forget the welding torch and abrasive cutting discs; this innovative solution offers a cleaner, more efficient, and ultimately more cost-effective method for returning your pump to peak performance. Let's dive into the detailed, no-cut repair procedure.

Preparation and Safety Guidelines

- Dremel tool with cutting tip

- Hammer

- Screwdriver

- PVC pipe glue

- Primer

- Always disconnect the pump from the power source before attempting any repairs. Electricity and water are a dangerous combination.

- Wear appropriate safety gear, including gloves and eye protection, to prevent injury from sharp edges or chemicals.

- If you are unsure about any step of the repair process, consult a qualified plumber or pump technician. Improper repair can lead to leaks, damage, and potential safety hazards.

Step-by-Step Instructions

Prepare Front Union

- Cut off the end of the union, right up to the pipe edge to facilitate easier separation.

- Use a Dremel tool to cut through the first layer of the union. The tool should not cut through the second layer.

- Use a hammer and screwdriver to pry off the cut union piece.

Prepare Front Union Prepare Back Fitting

- Repeat steps 1-3 for the back fitting, which may require more effort due to its loose position.

Prepare Back Fitting Clean and Prepare

- Clean the pipe ends.

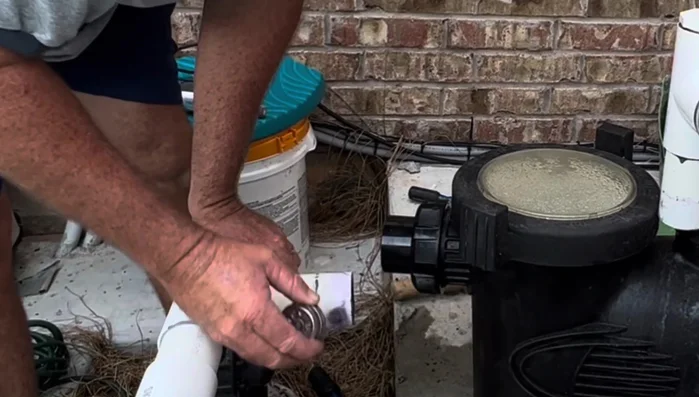

Clean and Prepare Install New Collars

- Install the new collars.

Install New Collars Assemble Front Union

- Attach the front union and tighten it to ensure a good seal.

Assemble Front Union Prime Connections

- Prime both connections (front and top) with pipe glue primer.

Prime Connections Install Top Fitting and Pump

- Install the top fitting first, ensuring correct height by pressing it into place and then sliding the pump underneath.

Install Top Fitting and Pump Final Tightening

- Tighten all connections.

Final Tightening

Read more: How to Easily Switch Between Presta and Schrader Valves on Your Bike Pump

Tips

- Use a Dremel tool with a tip suitable for cutting PVC. It should cut through the first layer but not the second.

- It's crucial to get the height right when installing the top fitting to ensure proper pump placement and function.