That satisfying "ding!" of a bike bell – a crucial safety feature – can be silenced unexpectedly by rust and neglect. A rusty, unresponsive bell not only compromises your safety but also detracts from the joy of cycling. Many cyclists discard a malfunctioning bell, assuming repair is too complex or costly, but this isn't necessarily true! Often, a little elbow grease and some basic tools are all you need to restore your bell to its former glory, saving you money and the environment. We're talking about simple solutions to common problems – from freeing up seized mechanisms to tackling stubborn rust.

This guide will equip you with the know-how to diagnose and effectively fix a range of bike bell malfunctions. Forget replacing your perfectly good (but currently silent) bell; let's dive into a step-by-step process that will have you ringing your way to safety in no time!

Preparation and Safety Guidelines

- Steel brush

- 1000 grit sandpaper

- Always wear safety glasses to protect your eyes from flying debris when disassembling and cleaning the bell.

- Use appropriate tools for the job; avoid using excessive force, which could damage the bell or injure you.

- If you're working with solvents or lubricants, ensure adequate ventilation and follow the manufacturer's safety instructions.

Step-by-Step Instructions

Inspection and Disassembly

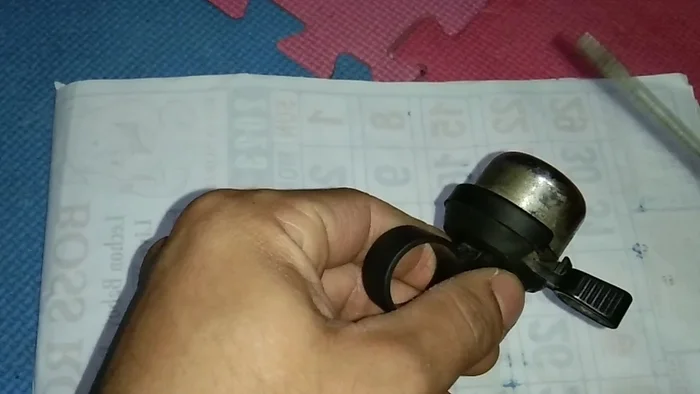

- Inspect the bike bell. Identify the source of the problem (rust and dirt).

- Carefully open the bell mechanism. Note that this particular bell doesn't have screws, it may need to be pulled apart.

Inspection and Disassembly Cleaning

- Clean the internal components. Use 1000 grit sandpaper to gently remove rust and dirt from the metal surfaces. A steel brush can be used for tougher areas, but be careful not to scratch the metal.

- Clean the inside of the bell mechanism as thoroughly as possible, even areas difficult to reach with fingers.

Cleaning Reassembly

- Reassemble the bell components. Pay close attention to the spring placement (small spring first, then the larger one).

Reassembly Testing

- Test the bell. It should now ring properly.

Testing

Tips

- Use 1000-grit sandpaper to avoid scratching the metal during cleaning.

- Be gentle while disassembling and reassembling the bell to avoid damaging the delicate parts.

- If possible, oil the spring mechanism for smoother operation.